Trick Advantages of Using a Membrane Switch in Industrial Applications

Trick Advantages of Using a Membrane Switch in Industrial Applications

Blog Article

Understanding the Functionality of Membrane Switches Over for Interface Instruments

The functionality of membrane layer switches represents a substantial improvement in individual interface style, integrating efficiency with visual versatility. As markets increasingly focus on user experience, recognizing the nuances of membrane layer button innovation becomes crucial.

What Are Membrane Buttons?

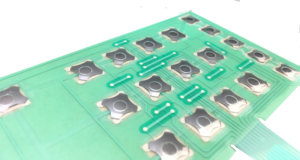

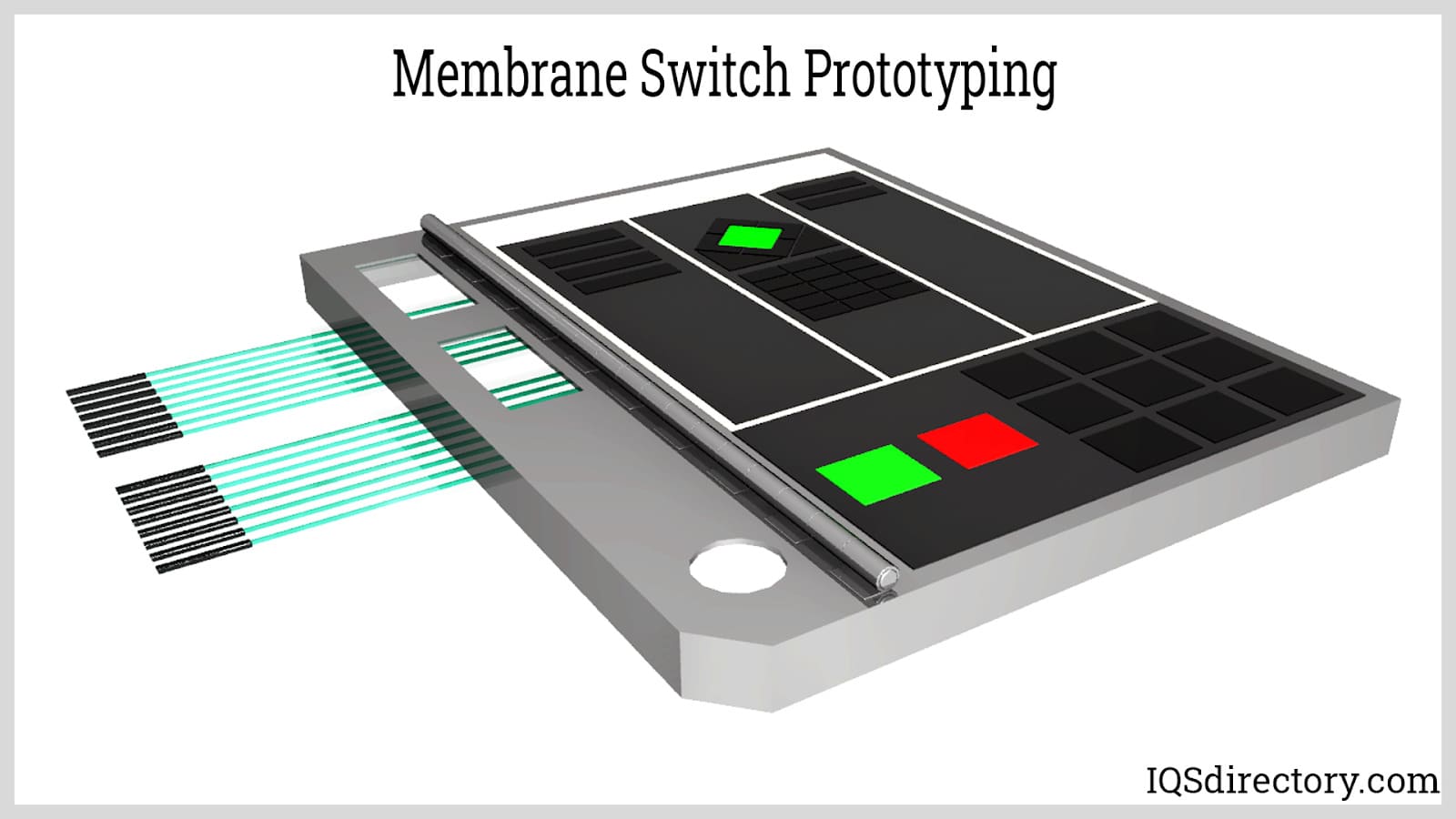

Membrane switches are cutting-edge interface devices that promote individual communication with digital tools. These versatile components consist of numerous layers, consisting of a visuals overlay, spacer, and a published circuit layer. The style enables for a seamless assimilation into numerous electronic tools, improving both the aesthetic and functional aspects of interface.

Membrane buttons are typically utilized in a vast array of applications, from house appliances to industrial machinery and medical tools. Their building generally features a slim account, making them a perfect selection for compact layouts. The tactile feedback given by these buttons can be engineered to fulfill specific customer choices, making certain reliable interaction between the user and the device.

Durability is one more considerable advantage of membrane layer switches, as they are resistant to dust, wetness, and chemicals, which enhances their lifespan sought after atmospheres. Furthermore, these buttons can be personalized in regards to form, dimension, and visuals design, permitting branding and user-specific features. Generally, membrane switches over stand for a useful service for improving user experience in electronic gadgets, combining capability with aesthetic allure in a reliable manner.

How Membrane Switches Job

Operating on a straightforward concept, membrane changes use a split building to sign up individual input effectively. Each button contains numerous layers, including a published circuit layer, a spacer layer, and a top graphic layer, which are developed to function together seamlessly. When a customer presses the leading layer, it compresses the spacer layer, bringing the conductive components of the circuit layer into contact with each other.

This contact develops a shut circuit, indicating the device to perform a particular feature. The style enables for numerous arrangements, including responsive comments, which can improve the individual experience by supplying a physical sensation upon activation. The products used in membrane buttons commonly include versatile substratums, such as polyester or polycarbonate, which make certain longevity and strength versus damage.

Trick Benefits of Membrane Switches

One more considerable advantage is their density. Membrane layer switches are slim and lightweight, which makes it possible for makers to conserve space in their tools without giving up functionality. This attribute is specifically beneficial in applications where weight and quantity are crucial considerations.

Additionally, membrane layer buttons are resistant to dirt, wetness, and chemicals, improving their toughness. This durability extends their lifespan and minimizes the learn this here now requirement for frequent replacements, resulting in expense financial savings in time.

Furthermore, the tactile responses supplied by membrane layer buttons can be enhanced to improve individual interaction. They can consist of features such as elevated switches or audible clicks, improving use and user experience.

Applications Throughout Industries

Interface tools using membrane layer switches are common in a wide array of sectors, showcasing their flexibility recommended you read and capability. Membrane Switch. In the clinical field, membrane layer switches are essential to devices such as analysis devices and patient tracking systems, where their longevity and ease of cleaning are crucial for maintaining health standards. In the automobile industry, these switches are used in dashboard controls and infotainment systems, providing a smooth and modern user interface for individuals.

Moreover, the customer electronic devices market take advantage of membrane layer switches in devices and handheld tools, where small style and straightforward user interfaces improve individual experience. Industrial applications additionally utilize membrane switches over for control board in equipment and automation systems, emphasizing their effectiveness and resistance to rough environments.

In the aerospace and protection sectors, membrane switches are utilized in cockpit controls and equipment, where dependability and efficiency under severe problems are critical. Additionally, the video gaming industry significantly includes membrane layer switches in controllers and arcade makers, adding to an interesting customer experience. On the whole, the adaptability of membrane switches allows their widespread usage throughout numerous markets, highlighting their importance in modern-day individual interface style.

Future Fads in Membrane Switch Modern Technology

Furthermore, making use of advanced materials, such as polycarbonate and polyester movies, is expected to increase, supplying improved longevity and resistance to ecological stress factors. These products contribute to the overall longevity of membrane buttons, making them suitable for harsher industrial applications.

In addition, the unification of wise innovation, including IoT connection, will make it possible for membrane layer buttons to interact with various other devices and systems, helping with a more interactive individual experience. This trend aligns with the growing need for smart tools across numerous sectors, from health care to customer electronic devices.

Finally, personalization options are prepared for to expand, permitting suppliers to create bespoke remedies tailored to particular customer needs and preferences. These developments will place membrane layer switches as important elements in the advancement of individual interface technology.

Final Thought

In final thought, membrane switches represent an essential development in user interface technology, supplying a reputable and versatile remedy for varied digital applications. As developments in material science and touch noticing innovations continue, the performance and applicability of membrane buttons are expected to increase, reinforcing their importance in modern electronic devices.

Report this page